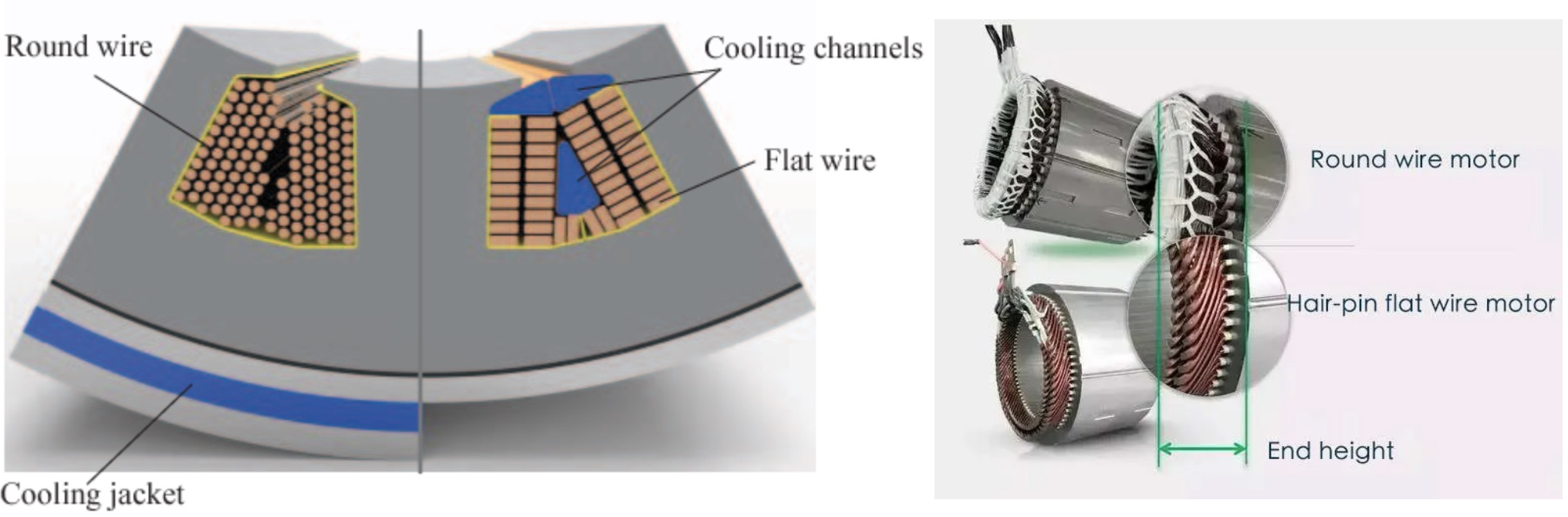

A flat wire motor refers to a motor in which the traditional cylindrical enamel-coated copper wires in the stator winding are replaced with enamel-coated copper flat wires processed into hairpin shapes. In the cross-section of the stator of a round wire motor, there are significant gaps left between the circular copper wires. However, in the cross-section of a flat wire motor’s stator, regular copper wires can better fill the space, increasing the slot fill factor. This fundamental difference is what sets flat wire motors aspart from round wire motors.

Compared to traditional round wire motors, flat wire motors can achieve a 20%-30% increase in slot fill factor. Technically, round wire net slot fill factor is generally about 40%, while flat wire net slot can increase to 70%, because the circular cross-section of round wire, irregular gaps between conductors are inevitable, whereas the gaps between flat wires are smaller, resulting in a higher slot fill factor. The higher slot fill factor translates to the motor being able to output higher power and torque under the same volume conditions, or having a smaller outer diameter and volume under the same power conditions. Consequently, flat wire winding motors have a higher power density, enabling permanent magnet motors to continue their development towards miniaturization.

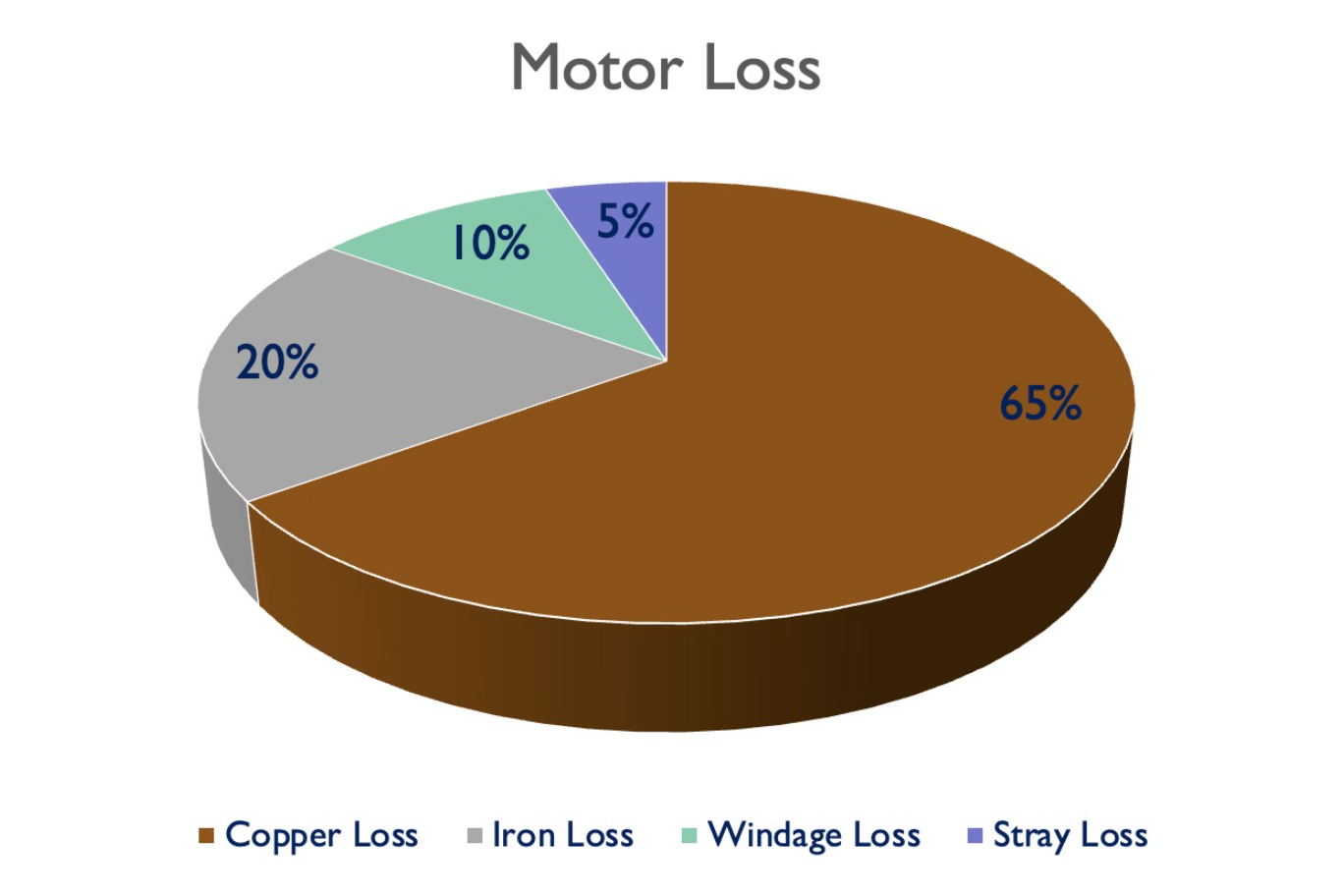

Motor loss is a significant root cause impacting the motor efficiency and motor power density. In a permanent magnet motor, motor losses include 65% copper loss, 20% iron loss, 10% windage loss, and other stray loss. It is understood copper loss results from the Stator Coil winding, while Iron loss is consisted of the Stator Core loss and Rotor Core loss. Copper loss is taking the most percentage of motor loss, flat wire motor and round wire motor are presenting the same level Iron loss, so the biggest difference relies on the copper loss.

When it comes to Copper loss, it can be divided into DC loss and AC loss. Both round wire and flat wire windings have DC losses, but for round wire windings, due to the smaller cross-sectional dimensions of individual windings, AC losses are almost negligible. However, for flat wire windings, AC losses are significant due to the larger conductor cross-sectional dimensions and the influence of skin effect and proximity effect.

Regarding DC losses, under given conditions of phase number and effective current value, DC losses are directly proportional to the DC resistance of the winding. Since round wire is thinner and has higher resistance, the DC losses of round wire motors are typically higher than those of flat wire motors under the same conditions. According to simulation calculations were conducted in finite element software for a 35 kW rated power permanent magnet synchronous motor. The DC losses for round wire winding were 19% to 36% decease than the DC losses in flat wire winding. In terms of AC losses, in high-speed rotating motors, the stator coils generate back electromotive force and produce eddy currents due to the cutting of magnetic flux lines. The magnetic flux that generates stator eddy currents consists of three main components: the motor's fundamental frequency magnetic flux (fundamental wave), stator slotting, core saturation, and internal harmonics generated by rotor movement, as well as external harmonics generated by PWM inverters. Simultaneously, due to the skin effect and proximity effect caused by alternating currents, AC losses will be further increased.

Obviously the tighter contact between flat wires, can dramatically improve the heat dissipation. Flat wire motors have superior heat dissipation performance showing the temperature rise is reduced by 10% compared to round wire motors. More researches have found that the thermal conductivity between windings at high slot fill factors is 150% higher than at low slot fill factors. The windings have anisotropic thermal conduction, where the axial thermal conduction capability is 100 times higher than the radial direction. With lower temperature rise conditions, the vehicle can achieve better acceleration performance.

The quieter vehicles bring drivers and passengers advanced experience, low electromagnetic noise is a continuous pursuit. Flat wire motor conductors experience higher stress and rigidity, resulting in better armature stiffness, which helps suppress armature noise. Smaller slot dimensions can be used, effectively reducing cogging torque and further reducing electromagnetic motor noise.

It is so beneficial to take advantage of the higher slot fill factor of flat wire motors, small size leads to high integration efficiency, in line with the trend of multi-in-one electric drive, where the amount of copper wire and corresponding stator for the same power motor is reduced. Additionally, flat wire motors have more advanced winding methods, allowing for easier trimming of the motor ends. Compared to round wire motors, the end dimensions can be reduced by 15-20%, further reducing the space required and achieving motor miniaturization and lightweight design.

Everything has two sides, the large-scale application of flat wire motors also needs to overcome some drawbacks, such as low yield rate, limited maximum speed, challenges in standardization, and patent barriers. In high-end vehicle models, to meet the demand for high performance, the number of flat wire motors used is increasing from single motors to dual motors.

Multiple special requirements for performance of electric motors in new energy vehicles are primarily manifested in high power density, wide speed regulation range, high starting torque, broad efficient operating range, and strong heat dissipation demand. Therefore, the development trend of electric motors for new energy vehicles also revolves around these performance issues of interest. Among several mainstream directions of EV motor development, flat wire motors are more and more predominating the development advancement. Currently,, there are increasing numbers of vehicle models using flat wire winding motors, including Tesla Model 3/Model Y, BYD Qin PLUS DMI, Toyota Prius, Volkswagen ID4 and others.

More about EV Motor, contact Quadrant now.