Material & Manufacturing

Efficiency in Material Fabrication

It is our mission to increase efficiency and reduce cost in the fabrication and operations of equipment. Material wire saw cutting is an integral process for most of our products. We slice magnet size down to a 25μm thickness with optimized wire saw equipment and processes. Quadrant continues to make improvements in our ID cutting, wire electrical discharge machining (WEDM), laser, waterjet and other cutting processes.

Sintered NdFeB

Grain Boundary Diffusion (GBD)

Chemical optimization and process enhancements have allowed Quadrant to achieve higher coercivity (HcJ) without reduction of remanence (Br). Quadrant developed a Rotary GBD technique that has enabled greater progress in this quest, while keeping the efficient HRE usage of Dy/Tb for cost benefit. It is a significant enhancement for small piece parts of Nd-Fe-B magnets.

Manufacturing

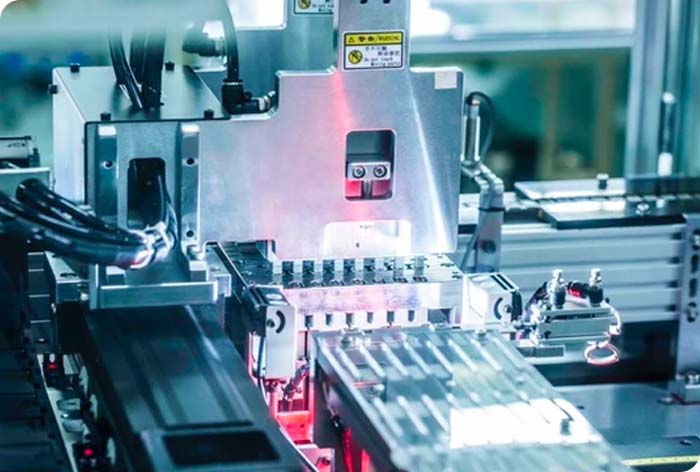

AI & Automation

Quadrant’s machine learning systems use modeling with iterative process control and measurement-data analysis to guide our lean manufacturing. Automated manipulators and conveyors move product through assembly, magnetization, and packaging operations with fail-safe fixtures and processes. CCD, laser optical inspection tools work with our inline magnetic inspection systems to ensure quality products.

Clean Energy

Soft Magnetic Materials

Amorphous, Nanocrystalline Alloys

The never-ending advancement of sophisticated electronic products requires the continuous development of increasingly complex materials. Quadrant excels in the mass production of customizable, ultra-thin, nanocrystalline strip materials. These polycrystalline materials exhibit Js>1.7T even with the extremely low Hc of 1A/m.

Sintered NdFeB

Coating / Plating

Quadrant’s various coatings lines offer solutions such as electro, electroless and vacuum platings, as well as thermal sprays and chemical treatment. We supply parts with thin or thick coatings with materials from Platinum & Parylene to Nickel & Epoxy. These surface treatments improve wear and corrosion resistance of vulnerable metals as well as enhancing the appearance.

Quadrant is committed to the sustainability and environmental coating solutions, we enjoy opportunities to develop innovative coatings that passed the Environmental Protection Policy.

Quadrant is committed to the sustainability and environmental coating solutions, we enjoy opportunities to develop innovative coatings that passed the Environmental Protection Policy.

Haptic Motors

Haptic Technology

Haptic technologies uses a vibrating component motor which is driven by an electronic circuit. Quadrant’s haptic motor portfolio includes Coin (“Pancake”) Vibration Motors, Linear Resonant Actuator (LRA) Motors (Z-axis), ERM Cylinder Motors, and Sonic Motors. We are continuously developing new haptic technologies to simulate improved tactile sensations and make the interaction more precise.

Motors

Drone technology

Quadrant has been working with a variety of Drone motor applications for in the air and under water usage. We design and manufacture brushless motors and components to meet customer requirements for greater torque, speed, and energy efficiency.