Mechanical and magnetic property tolerances influence the effectiveness of permanent magnets and can be uncontrollable past a point due to production techniques and costs. These different tolerances cause similar magnets to induce different magnetic fields. For this reason, measured results can vary between similar same batch magnets. As the producer of the magnets, it is important to have some control over the specific requirements. Many users have needs for specific requirements to be met. Here we can see the effect of different tolerances between similar magnets depending on the magnet’s size, materials, and position. We will gain an understanding of how different tolerances affect the holding force.

The tolerance of the magnet depends on the method of production. Manufacturing result in a slight difference in size of the magnet. These differences in size can have an impact on the resulting magnets properties. Magnets produced in the same batch will tend to have different magnetic properties but fall within a tolerance range set for the specific magnet type. Rarely are magnets as precise as simulations due to minor differences in real-world manufacturing.

When different magnet material types are used the resulting magnetic properties differ even when the magnets are similar in shape and size. It is important to account for differences early in production to prevent increased production costs. These magnetic properties will depend on the user’s needs. That being the intended use, temperatures, and force required to meet their production needs. Control of the tolerances is needed to make sure that these needs are met when producing the required magnet types. The Magnetic Materials Producers Association has set a standard for production of permanent magnets. Those standards are: ±5% for residual induction and ±8% for coercivity.

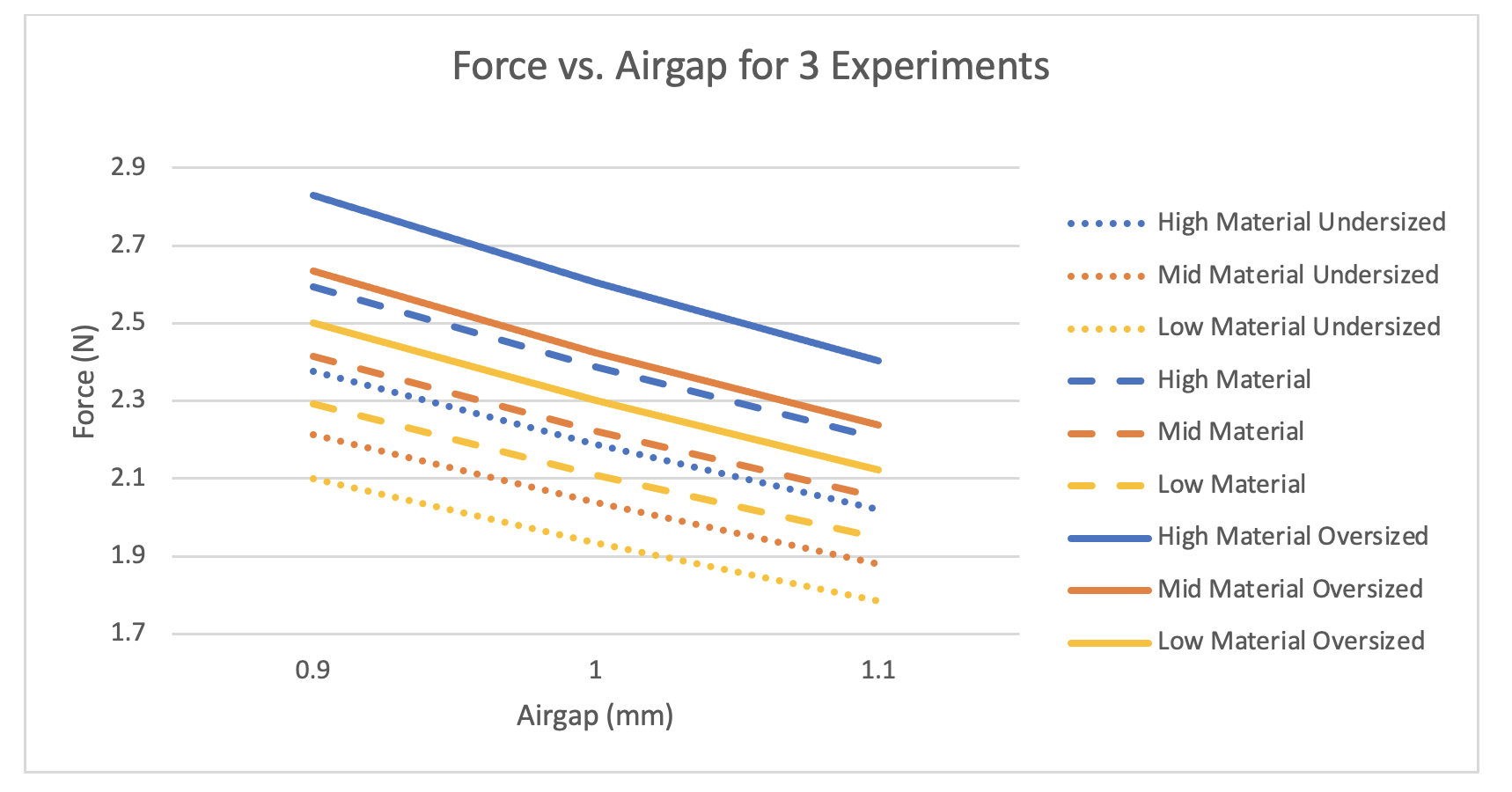

The following figures are the simulated data of magnetic holding force to discuss the difference of tolerance effect on material types. The magnet’s intended size is 4x4x2mm and was increased and decreased by 0.05mm to simulate the tolerance change in manufacturing. The airgap was also shifted by 0.1mm each direction to simulate the placement tolerance of the magnet and any coverings. Finally, the material properties from the production block were varied within the acceptable property range.

Figure 1 – Force effects of magnetic tolerances

Tolerance on magnets can have a big impact on the magnetic function and cost of production. For that reason, it is important to understand what is acceptable to the customer. Depending on their limits, different magnetic production methods may be used to produce the magnets with tolerances that closely match the required force. As seen on the figure above, slight differences in size can influence the magnetic properties. These differences make it important to understand the possible changes that can occur in manufacturing. It can be seen from the data that the mechanical (dimensional) tolerances have a slightly stronger affect than the material property changes. However, both have a drastic effect on the holding force, the working gap of course being the most important.