Metal Injection Molding (MIM) is a transformative manufacturing process that combines the design flexibility of plastic injection molding with the strength and integrity of metal. This technology allows for the production of complex metal components with precision, making it a popular choice in industries requiring high-performance parts.

The Metal Injection Molding Process

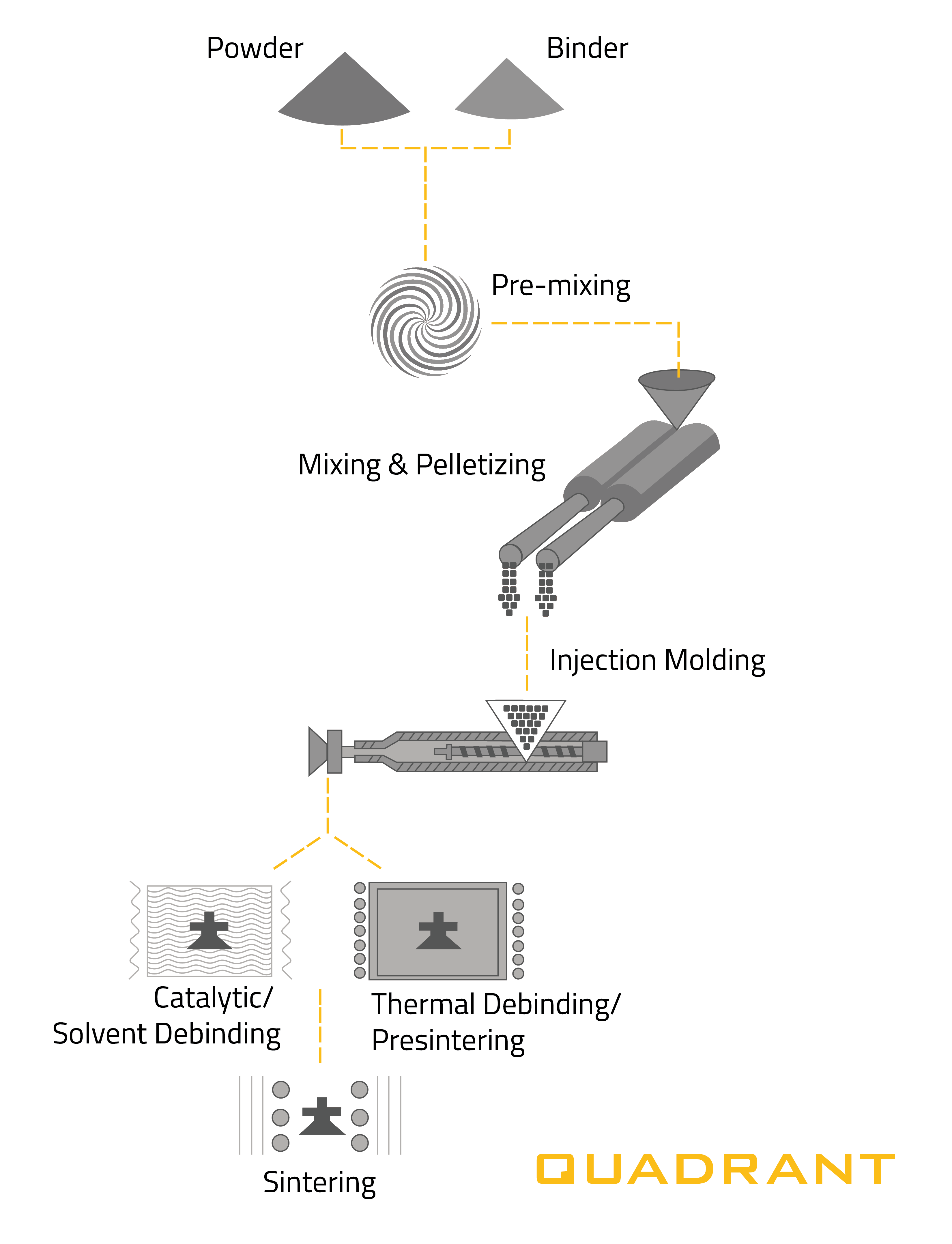

The MIM process begins with fine metal powders and a binder system, which are mixed and pelletized to form a feedstock. This feedstock is then injected into a mold using high-pressure injection molding, similar to plastic injection molding. After molding, the binder is removed in a process known as debinding, and the metal component is sintered at high temperatures to achieve its final properties.

Key Manufacturing Steps:

Powder IQC and Feedstock Preparation: The process starts with stringent quality control of the metal powders, such as FeSi powder mixed with POM (Polyoxymethylene) to form the feedstock. The feedstock is prepared by mixing the materials at 200°C for 120 minutes.

Injection Molding: The prepared feedstock is injected into molds at precise temperatures (around 205°C) and pressures (180 MPa), using machines like the FANUC α-S50iA.

Debinding and Sintering: Post-injection, the parts undergo debinding to remove the binder, followed by vacuum sintering at temperatures as high as 1380°C. This sintering process densifies the metal, creating parts with high mechanical properties.

Post-Sintering Operations: The sintered parts are subjected to processes such as re-striking, polishing, sand blasting, and plating, ensuring the final product meets the required specifications. Each step is crucial to achieving the desired surface finish, dimensional accuracy, and overall quality.

Quality Control and Packaging: Comprehensive inspections, including Automatic Optical Inspection (AOI) and cosmetic inspection, ensure each part meets stringent quality standards before packing.

Materials Used in Metal Injection Molding

| Stainless Steel | Soft Magnetic Alloy | Low Alloy Steel | High Density Alloy | Tool Steel | Special Alloy | Ceramic | Plastic |

|---|---|---|---|---|---|---|---|

| 17-4 PH | FeSi3 | FN02 | W-Ni-Fe | M2 | Ti/Ti-6Al-4V | AL2O3 | PA |

| 316L | FN50 | FN08 | W-Ni-Cu | SKD11 | F15 | ZrO2 | PPS |

| 304 | FeCo35 | G1010 | W-Ni-Co | 4J29 | ABS | ||

| 420 | FeCo50 | 8620 | GHS-4 | PE | |||

| 430 | FeCo49V2 | 8740 | HX | PS | |||

| 440 | Ni80 | 4340 | N90 | POM | |||

| 2507 | 100Cr6 | LCP | |||||

| PANACEA | 42CrMo4 | ||||||

| F75 | SCM415 |

Applications of Metal Injection Molding

MIM is employed in a variety of industries due to its ability to produce intricate parts with tight tolerances and superior mechanical properties.In the automotive industry, MIM is utilized for the production of critical components such as gears, turbocharger parts, and fuel system elements, where high strength and precision are paramount. The medical sector benefits from MIM technology in the manufacture of surgical instruments, orthodontic brackets, and implants, which require biocompatibility and precise dimensions. Electronics manufacturers rely on MIM to create components for mobile devices, sensors, and connectors, all of which demand miniaturization and reliability. Additionally, the aerospace industry employs MIM to produce complex parts used in engines, airframes, and fuel systems, where lightweight and durable materials are essential. The versatility and efficiency of MIM make it an indispensable technology in these high-tech fields, enabling the production of parts that meet rigorous standards of quality and performance.

Quadrant leverages automation in the MIM process to enhance precision, efficiency, and consistency. Automated systems cover the entire production process, reducing labor costs and minimizing human error. This comprehensive approach ensures high-quality output and reliable performance, making MIM an ideal choice for producing high-volume, precision components. Contact us to learn more.