In various motor applications, higher motor efficiency is desired to obtain, where the motor can convert as much electrical energy into mechanical energy relative to the input power, generating less energy waste, since it is comprehensively impact the operating costs, power consumption and environmental sustainability.

When it comes to the energy loss, that directly impacts the motor efficiency, the primary culprit should be the heating issue. Motor internally produces amount of heat while it is operating, we can categorize several sources caused the heating generation, copper losses takes the first place, then iron losses, mechanical losses and wind resistance losses. Mechanical losses typically comes from bearing friction, commutator/brushes abrasion (for DC brushed motors), and mechanical components interfaces wearing. Wind resistance is commonly caused by air resistance. Mechanical and wind resistance losses are usually relatively accounting smaller in the overall energy loss, therefore they are often ignored in analysis.

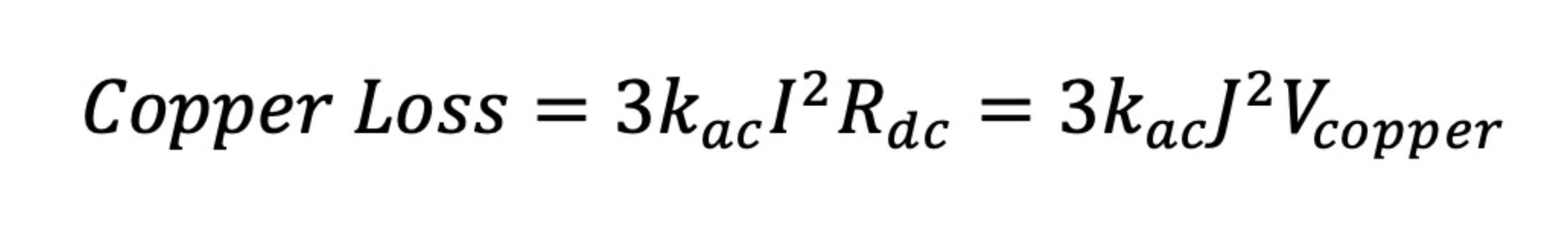

Copper losses, as the biggest factor contributing to inefficiencies in motor operation, refers to the energy loss occurring in the copper windings of motor due to the electrical resistance of the copper wires. Some of the electrical energy is wasted as the form of heating because of the wire resistance when current flows through the copper windings. Copper loss is typically calculated by this formula: Copper Loss=I²R, where I represents Current, which is proportional to the square of the current, R represents the electrical resistance of the coil, indicating the higher the resistance, the greater the copper loss.

We can also use following calculation formula to find out the relationship between copper loss and torque. Copper loss is proportional to the square of the current, and torque is proportional to the current, therefore copper loss is proportional to the torque.

Seen from above calculation formulas, we can find ways to decrease the copper loss, reducing the flowing current in the coils and reducing the resistance of the coils. Bigger diameter copper wire is helpful for the resistance reduction, and the maximization of filling factor. However, enlarging the copper wire still cannot control the heating effectively, that’s why cooling to the coils is highly required.

Using a fan for forced air cooling is an effective and simple method, but it requires the motor to have an open structure. Considering dust and water resistance, forced air cooling is not suitable for motors used in electric vehicles (EVs). The liquid cooling forms of automotive permanent magnet synchronous motors can be roughly divided into two types: direct cooling and indirect cooling. Indirect cooling involves designing cooling passages inside the motor housing, allowing coolant to flow through the entire housing and carry away heat. Direct cooling, on the other hand, involves injecting cooling oil directly into the sealed motor. The cooling oil, with its higher specific heat capacity, is utilized for cooling purposes. Additionally, direct cooling allows for increased contact area with the heat source, resulting in better cooling effectiveness. The end portions of the windings in permanent magnet synchronous motors generate significant heat. In water cooling, the coolant cannot directly contact the windings, but in oil cooling, the cooling oil can directly come into contact with the windings, leading to higher cooling efficiency and more pronounced advantages.

In oil cooling technology, the cooling oil can directly come into contact with the heat-generating components of the motor, resulting in significantly higher heat dissipation efficiency compared to traditional water cooling systems. Additionally, the oil medium possesses advantages such as good insulation properties, high dielectric constant, low freezing point, and high boiling point.

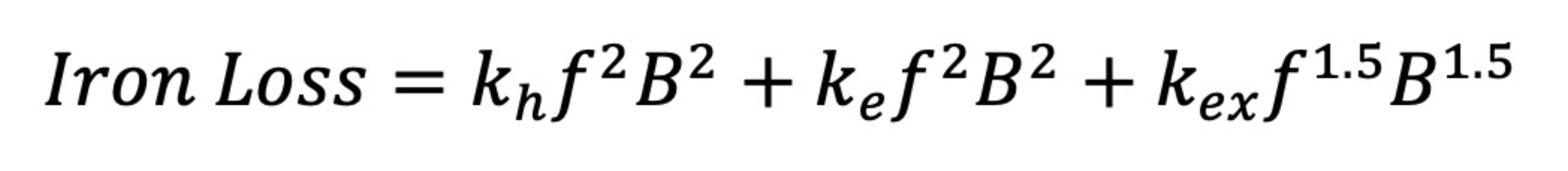

For the iron loss, there are two main type, including Hysteresis loss and Eddy current loss. Magnetic materials themselves produce energy consuming when the direction of the magnetic field is changed. In magnetic materials, many small magnetic domains are aligned in the same direction. If the direction of these domains are affected by the external magnetic field, energy is consumed in this situation. High-quality ferromagnetic materials typically require less energy to change the direction of magnetic domains, presenting lower hysteresis loss. When the magnetic flux strength or direction changes in the magnetic circuit, or the electrical currents in the electrical circuit, eddy currents in closed loops are generated to oppose this change. The heating caused by eddy currents in Joule heating is called as eddy current loss.

There are some measurements can be conducted to reduce the eddy loss. Select or improve magnetic materials to reduce hysteresis loss, but low-loss materials often come at a higher cost. Increase the materials’ resistance, for example, adjust the silicon content in silicon steel sheets, or design the motor’s iron core into laminated sheets with electrical insulation treatment to reduce eddy currents.

Additionally, hysteresis loss is directly proportional to frequency and proportional to the square of magnetic flux density, whereas eddy current loss is proportional to the square of frequency and the square of magnetic flux density. Therefore, when designing a motor, it is required the dedicated considerations of pole number binding to the frequency, and magnetic circuit related to effective magnetic flux and magnetic flux density.

If the iron loss needs to be completely eliminated, we can try to remove components that causes the iron loss, such as iron cores and yokes. For example, the coreless "cup motor" is an option, which has the advantages of small size, light weight, good starting performance, and no cogging effect, thus achieving smoother operation. Such motors are common in wireless remote control models. Yokes are crucial in determining magnetic flux paths; some motors do not use yokes but instead use iron enclosures called magnetic pole covers to enclose the magnetic circuit. From below calculation formula of iron loss, it is proved the iron loss is approximately proportional to the square of frequency, and frequency is proportional to the motor rotation speed, therefore the iron loss is proportional to the speed.

During motor’s normal operation, both iron loss and copper loss cause heating issue, but either dominates at different working conditions, forming different efficiency distributions accordingly. For example, from no loading to stalling of motor operation, heating mainly comes from the iron loss, while almost 100% heating is caused by the copper loss.

At Quadrant, we specialize in optimizing motor designs to achieve maximum efficiency and performance. Contact us today to learn how our expertise and innovative solutions can benefit your projects and drive your success in the motor industry.