Can you speak out the best transmission solution always? No, I don’t think we can. There are 4 mainstreaming transmission methods that are widely utilized in different cases and fields, including Pneumatic transmission, Hydraulic transmission, Mechanical transmission and Electrical transmission. I prefer to say none of them is perfect in all cases, each of them shows the advantages and disadvantages, however, we are able to find out some adoption directions to make full use of their strengths in proper scenarios. Here are some and small tips you can take away really focused on the advantages and disadvantages analysis for each of above transmissions.

As Electrical transmission is highly precise, accurately controllable, energy saving, less noise, environment friendly and cost saving, it’s my preferable transmission, but not limited and not the ideal one all the time.

Electrical transmission is power driven by the servo motor, coupling with a transmission mechanism, like ball screw and synchronous belt, which is in a very simple structure yet highly efficient. It’s data analyzed the repeatability error to be around 0.01%, amazing precision. With the support of high-precision sensors, measuring devices, and computing technology, accurate control can be obtained based on parameters setting, surpassing the control accuracy achievable by other control methods, and such precise control is supportive that lower than 70dB noise is produced while the operation.

The energy released during the deceleration phase of the operating cycle can be converted into electrical energy for recycling, saving operation costs. The connected electrical equipment accounts for only 25% of the power required for hydraulic drive equipment, resulting in reduced energy consumption and cost savings in automotive applications. In electrical transmission system, hydraulic oil elimination contributes to cost reduction as well, and less issues. Meanwhile, it is highly effective on coolant cost down, no cooling is required onto the hydraulic oil. Less variety and optimized performance of energy sources, pollution sources have decreased, and noise has been reduced, providing a better guarantee for the environmental protection work of the factory.

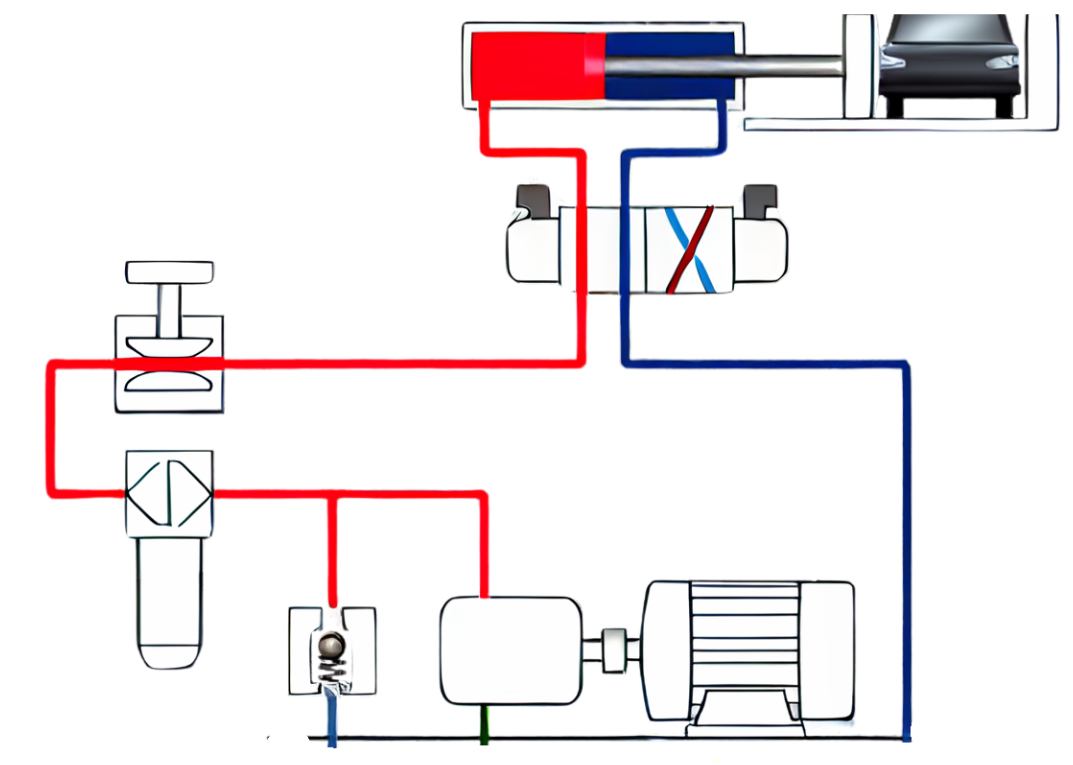

When it comes to the Hydraulic transmission system, which structurally excel in terms of both power output per unit weight and power output per unit size among the four types of transmission methods. They have have a significant torque-to-inertia ratio, resulting in smaller volume, lighter weight, lower inertia, compact structure, and flexible layout when transmitting the same power. In terms of performance, speed, torque, and power can be continuously adjusted with rapid response, quick reversal and speed change, wide speed regulation range (from 100:1 to 2000:1), and good agility. They offer simple control and regulation, easy operation, and compatibility with electrical control and CPU connection for automation. Economically, hydraulic transmission offers high plasticity and variability, enhancing production flexibility and facilitating changes and adjustments to production procedures. Hydraulic components have relatively low manufacturing costs and strong adaptability, but have good self-lubricating properties, easy implementation of overload protection and pressure holding, ensuring safety and reliability, components are easy to standardize, generalize and serialize. In addition, hydraulics can easily integrate with new technologies such as microcomputer control, forming a trend of “mechanical-electrical-hydraulic-optical” integration, facilitating digitization.

Of course, like everything else, Hydraulic transmission is subject to division. Leakage issue occurring in hydraulic transmission due to unavoidable relative motion between surfaces. Additionally, hydraulic fluids is not completely incompressible, and elastic deformation in components such hoses prevents strict transmission ratios, making hydraulic transmission unsuitable for inline transmission chains, such as those found in machine tools used for processing threaded gears.

Hydraulic transmission is not recommended for long-distance transmission, because its relatively low transmission efficiency resulted from various losses along the fluid flow, including the frictional losses, local losses, and leakage losses, etc. High and low temperature effects onto the hydraulic transmission cannot be ignored. To prevent oil leakage and meet certain performance requirements, high precision is required in the manufacture of hydraulic components, leading to difficulties in maintenance.

Fault diagnosis is challenging, especially in units where hydraulic technology is not widely understood. This contradiction often hinders the further promotion and application of hydraulic technology. Maintenance of hydraulic equipment relies heavily on experience, and training period for hydraulic technicians is typically lengthy.

Comparing to Hydraulic transmission, Pneumatic transmission is suitable to be used for long-distance transmitting and centralized air supply, because the air has low viscosity (~one-ten-thousandth of the dynamic viscosity of hydraulic oil), losses are minimal. Using air as the transmission medium, it’s easy to obtain and dispose after use by venting it into the atmosphere, making handling convenient, and no need to set up recovery tanks and pipelines, but hydraulic transmission does. Pneumatic transmission is cost-effective and provides automatic overloading, and not causing environmental pollution in the leakage. Pneumatic transmission offers rapid action, quick response, simple maintenance by using clean air, no degradation concern, hence it is well-suited for various application environments, especially in harsh conditions such as flammability, explosiveness, dust, strong magnetic fields, radiation, and vibration, where it outperforms hydraulic, electronic, and electrical controls.

However, pneumatic transmission speed of air signals in pneumatic devices is slower than that of electronic and optical signals, as it is within the speed of sound. Therefore, pneumatic control systems should not be used in complex circuits with too many components. It is required the additional muffler to prevent the significant noise that is specifically produced in high-speed exhaust. Due to the air compressibility, the working speed stability is not as ideal as expected, unless the air-hydraulic linkage devices are fully utilized.

The last member discussed is the mechanical transmission system, which is in multiple mechanical configurations, such as Gear Transmission, Turbine and Worm Gear Transmission, Belt Transmission and Chain Transmission.

Gear Transmission can be categorized into Planetary gear transmission and Spatial gear transmission. Gear transmission presents wide range of applicable peripheral speeds and power, accurate, stable and efficient transmission ratio. It is feasible to transmit between parallel axes, intersecting axes and axes intersecting at any angle via the gear transmission. Considering the stacking deviations of machining, assembling and mounting, high processing and installation precision are required, causing high cost, so not suitable for long-distance transmission between two shafts.

Turbine and Worm Transmission are suitable for motion and power transmission between two spatially vertical and non-intersecting shafts with large transmission ratio and compact structure, but it is generated large axial force, over heating, resulting in low efficiency. In addition, only on transmission direction is available in this type of transmission system.

Belt Transmission is including driving pulley, driven pulley and V-belt, and used for the open motion where two parallel shafts rotate in the same direction with the concept of center distance and wrap angle. Key points of applying the belt transmission is the calculation of transmission ratio and stress analysis calculation of belts, fortunately, three major types of belts of flat belts, V-belts and special belts based on cross-sectional shape. Belt transmission is proper for transmission with large center distances between two shafts. Flexible belts can cushion impact and absorb vibration. Belt slipping prevents damage to other components during overloading. Belt transmission has simple structure and low cost, but has larger overall dimensions of transmission, requires tensioning device. No fixed transmission ratio can be guaranteed due to slipping element, and lower transmission efficiency can meet.

Chain transmission, composed of driving chain, driven chain and roller chain, has lower requirements for manufacturing and installation accuracy, presents poorer transmission stability as the instantaneous chain speed and instantaneous transmission ratio are not constant. Learn more about what Quadrant has to offer, contact us!